Modernising a Kiwi-classic: Golden Goose Foods leverages EDI to scale their business

As your business begins to grow, it can be easy to get swept up in the euphoria of success - you end up focusing on the growth and forget about reviewing whether your processes are still up to the task. Growth usually comes with added complexity – more customers, bigger orders, increased production output and extra delivery locations, all of which you need to keep on top of.

The processes and systems that served you well up to this point may no longer be up to scratch, or the increased workload may generate problems that weren’t as prevalent or as costly when the business was smaller.

This was something Joanna Williamson from Golden Goose Foods was well aware of. When Jo and her husband bought the business, they not only wanted to modernise a Kiwi-classic, but also embrace the concept of using modern systems to drive productivity.

A modern product, a modern approach

Based in Christchurch, Golden Goose Foods is one of New Zealand’s leading hot dog producers. Their frozen hot dog on a stick is a high-quality product, differentiating it from the majority of the market. They’ve seen a lot of growth since 2008, and have plans of expanding into the Australian market in the near future. This growth led them to reviewing their processes and identifying areas that could be improved.

“As we were growing, we decided that we really had to look quite closely at what [Software as a Service] options were available...Because we’re not IT experts, we employed a company - BDO [Information Systems] in Auckland - that had a really good understanding of the kinds of systems that are available for SMEs like us. This is how we were introduced to Crossfire."

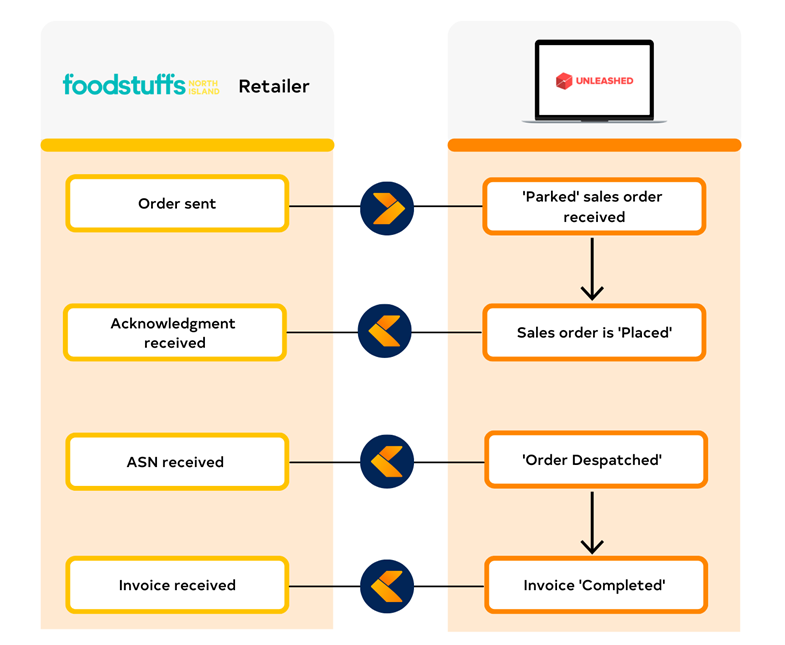

One of Golden Goose Food’s primary customers is Foodstuffs, a major New Zealand food retailer. Foodstuffs requires their suppliers to use Foodstuffs eXchange, a purpose-built supplier portal. Golden Goose would then receive an email containing order details, relying on those details to be added to their system manually.

“Prior to Crossfire, the process within our business [was] we would receive a customer order via email, and someone would have to physically enter that into the computer and then generate packing slips and invoices.”

The advantages of end-to-end integration

“We could immediately see the value of a system that would automatically pluck all our orders from Foodstuffs…and drop it into Unleashed, which is our manufacturing and order processing system.”

As the number and size of orders coming in grew, the time Operations team members were spending on data entry was increasing. This meant less time for completing other important tasks within their working day.

Automating this process, using our tried-and-tested Cloud EDI integration platform, heavily reduced the workload of Golden Goose’s team. “Now, with that order automatically sitting within our system, all we have to do is generate packing slips and invoices.”

Once their integrated system was up and running, the Golden Goose team discovered a wholly unexpected benefit, saving them from a headache that could spoil an entire day’s worth of work previously.

“Probably once or twice a month, an order would go out where the product had been incorrectly keyed or… the wrong customer might be entered into the order…[like] Pak’n’Save Blenheim [rather than] New World Blenheim... one error like that would take hours to correct. We found with Crossfire, it virtually eliminated all those errors and saved all that correction and chasing time of freight that had gone to the wrong places.”

Crossfire - the silent business partner

We worked very closely with Golden Goose Foods to ensure our integration system did exactly what they needed. “One of the great things we found [with Crossfire] was they literally babysat us through the whole of integrating with the Foodstuff’s system.”

An area where we helped Golden Goose with was loading individual barcodes into their system, creating a seamless process which ensured all their critical product codes lined up when orders were processed by the automated system.

“I kind of see [Crossfire] as our silent business partner…they gave us intensive support through the integration with Foodstuffs. We rarely have contact now because the system just operates silently in the background. On the very occasional time that we do need support, it’s always been very prompt and efficient.”

Investing in your future

By using effective processes and automation, your business can improve efficiency and cut costs.

But more importantly, you’ll be saving the time of your most important asset - your staff - letting them focus on other tasks within the business.

If you’d like some help in working out areas of your business where you can work smarter, not harder, get in touch – we’d love to help. We’ve helped businesses across all industry sectors, both here in NZ and internationally.

Learn More about Golden Goose Foods